Vacuum sewer systems are a state-of-the-art technology for sewage sewers that is particularly advantageous in certain morphological conditions of the terrain. Unlike traditional gravity and pressure systems, the negative (vacuum) pressure created by special vacuum pumps is exploited to suck and transport wastewater into the pipes.

Benefits

- Speed of implementation

- Reduced piping cross section

- Low installation depth

- Reduced and economical excavation

- Fully enclosed and odor-free system

- Absence of onerous pumping stations

- Ease of maintenance (including remote)

Application fields

- Settlements with low population density on flat land

- Settlements in soils with the presence of high water table

- Tourist settlements

- Settlements located on unfavorable soils (rocky or with danger of subsidence)

- Reconstruction of existing old sewers

- Sewerage networks in areas near lakes, rivers, coasts or particularly sensitive areas

Vacuum sewer systems

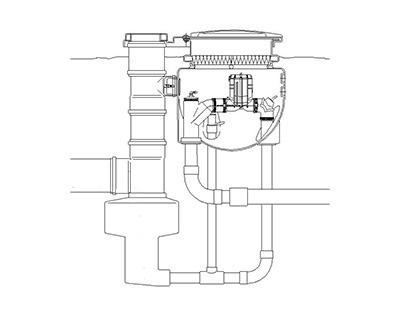

Interface well

Our unique interface well is laid outside buildings to be connected to the vacuum network and collects effluent from one or more settlements.

It is made entirely of PE, is perfectly waterproof and does not require electricity (pneumatic operation).

One part of the sump is devoted to wastewater collection, while another, completely separate and dry, contains the technique consisting of interface valve connected to the vacuum network and the pneumatic activator.

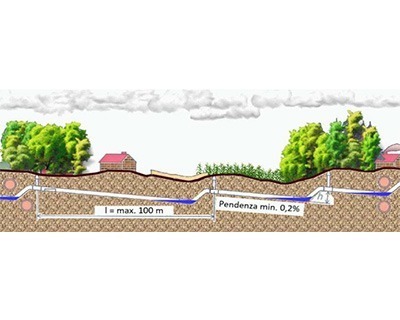

Vacuum network

The vacuum network can be made alternatively of PEHD or PVC.

The characteristic “sawtooth” profile ensures the perfect functioning of the system by creating in the lower part of the piping the necessary hydraulic plugs that are indispensable for the transport of wastewater to the vacuum station. Our technicians support designers in hydropneumatic calculation.

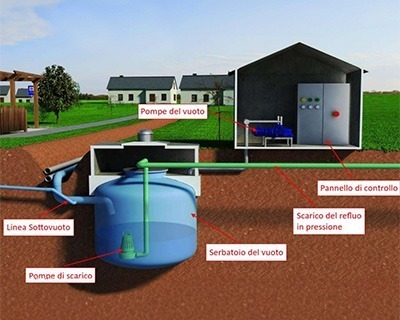

Vacuum station

The vacuum station can be considered the beating heart of the system. It is a modestly sized building in which the vacuum pumps and control panel are housed.

Roediger® Vacuum rotary vane vacuum pumps have the function of generating the vacuum (negative pressure) within the duct network necessary to ensure proper system operation.

The control panel is designed and built according to the customer’s needs. It is possible to equip it with a remote control system to simplify operation and maintenance.

The vacuum tank equipped with vacuum pumps to which all wastewater collected from the network flows is installed nearby. The tanks are made of painted steel and their dimensions vary according to the design data. The discharge pumps, either submerged or dry mounted, send the effluent to the final treatment (purifier) or to a possible gravity sewer system.

See our references

for these products

Check out

other products

other fields