Our vacuum port systems solve the management of two different types of contaminated water in ports:

- Black water from boat toilets and kitchens, which is stored in special tanks that need to be drawn periodically

- Bilge water, or water contaminated with mineral oil in the “engine room.”

Vacuum systems are ideal for suctioning these effluents in compliance with environmental regulations.

Benefits

- Elimination of marine pollution caused by untreated discharges

- Fast and reliable interventions

- Intuitive operation

- Hygienic and odorless system

- Can also be retrofitted to existing systems

- Can also be used to collect civil effluent from port settlements (stores, restaurants, etc.)

Application fields

Ports and all facilities attached to them

Vacuum port systems

Vacuum columns

The most suitable site is identified along the docks to install effluent suction columns. Made of stainless steel, there are a variety of types and are equipped with a suction pipe with nozzle fitted with: ball valve, vacuum valve, activator and 15 m long hose that allows the operator to discharge the effluent by pressing the start button. They are connected to the vacuum network that delivers to the vacuum station tanks.

Pipes network

The pipes network, is made with the classic sawtooth profile and is installed under the wharves or in the appropriate utility tunnels for water and power distribution.

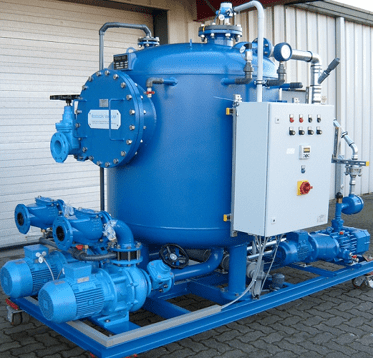

Vacuum station

The vacuum station is built according to the design data and consists of Roediger rotary vane vacuum pumps, effluent storage tank with discharge pump, and electrical control panel (all pre-assembled at the factory). In some installations it is possible to use the innovative Vacuum Stations that do not require a storage tank.

See our references

for these products

Check out

other products

other fields