Vacuum sanitary systems are an innovative solution for efficient wastewater management in indoor environments such as commercial buildings, apartment buildings, residential facilities, hospitals, airports and other installations where sewage management is critical.

Gravity sanitary systems in large settlements, in fact, usually manifest problems such as the need for long stretches of piping with poor gradients, the availability of limited space, lack of flexibility for overcoming obstacles or for changes during construction, and high water demand. Vacuum technology, applied to sanitary systems in large buildings, solves all these problems.

Benefits

- Reduced Water Consumption

- Construction versatility

- Reduced space requirements

- Smaller pipe sizes without slope that can be installed in suspended ceilings

- Clean and hygienic system

- Odorless, no inhalation

- Zero leakage

- Modifications implementable at any time

- Ease of maintenance

Application fields

Indoor systems of large buildings such as stadiums, shopping malls, museums, hospitals, airports, etc.

Sanitary vacuum systems

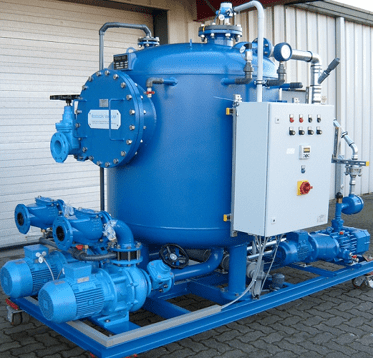

Vacuum station

The vacuum station, usually pre-assembled and located on the ground floor or basement, is the heart of the system. Rotary vane pumps create and maintain the vacuum at a pressure of -0.6 bar in the piping network. Wastewater flows into the vacuum tank and, when certain volumes are reached, is conveyed to the sewage treatment plant or sewage system via discharge pumps. The control panel manages its operation.

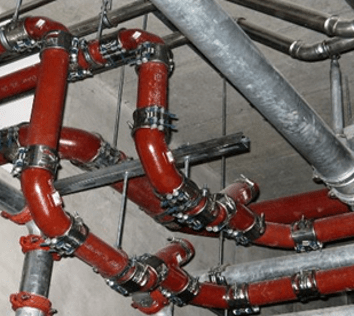

Neywork system

Pipes are made of PVC SDR 21, PEHD SDR 11 or cast iron, with reduced cross sections compared to conventional systems. The little slope required allows installation in false ceilings or subfloors. Special pieces called lifts, appropriately spaced, are used to bring the piping back to the elevation and allow simple overcoming of obstacles or changes in the location of sanitary fixtures.

Bathroom fixtures

Roediger vacuum toilets, available in various materials and for wall or floor mounting, operate by a pneumatic mechanism without the need for auxiliary power. They are equipped with an interface valve to the vacuum network and provide significant water savings, using less than one liter of water per operating cycle. Other utilities operate by gravity and their effluents are collected through special units equipped with a valve to connect to the vacuum system.

See our references

for these products

Check out

other products

other fields